A resin 3D printer is a type of additive manufacturing device that uses liquid resin materials to create three-dimensional objects. Unlike traditional filament-based 3D printers, which extrude plastic filament layer by layer, resin 3D printers employ a process called stereolithography (SLA) or digital light processing (DLP) to cure liquid photopolymer resins into solid objects.

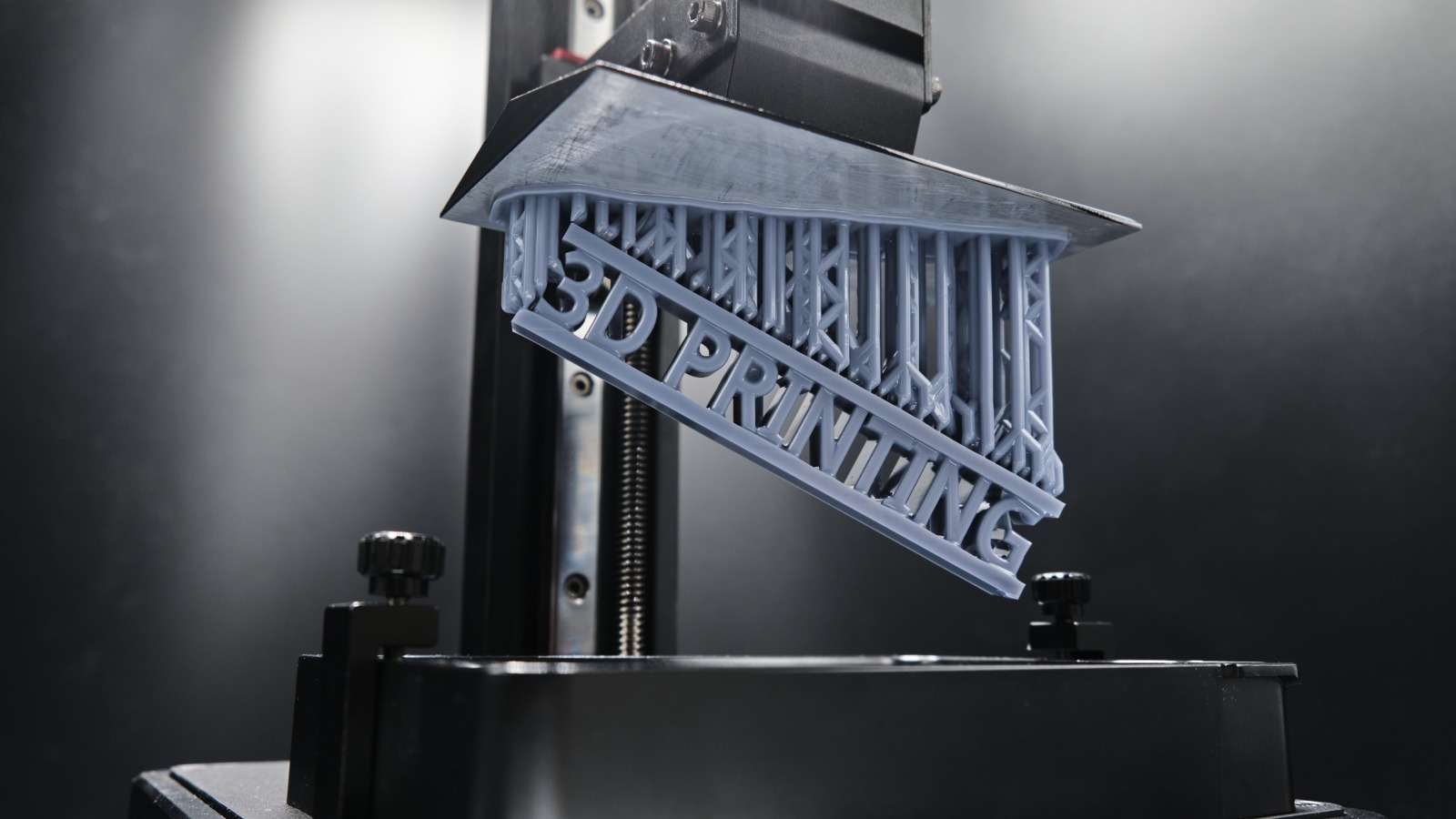

In a resin 3D printer, a build platform is submerged in a vat of liquid resin. The printer’s light source, typically a UV laser or a projector, selectively exposes the liquid resin to specific patterns of light, causing it to solidify and adhere to the build platform. As the object is gradually built up, the build platform either moves upward (in SLA) or the light source and/or resin vat moves (in DLP) to create successive layers.

Resin 3D printing offers several advantages, including the ability to produce intricate and detailed models with high precision. This technology is often used for creating small-scale prototypes, intricate jewelry, dental models, and other applications where fine detail and accuracy are crucial. However, resin 3D printing also comes with some limitations, such as the need for proper ventilation due to the fumes emitted during the curing process and the post-processing steps required to clean and cure the printed objects.

Overall, resin 3D printing has become a popular choice for industries and hobbyists looking to create highly detailed and precise objects, but it’s important to choose the right resin and follow proper safety procedures when using these printers.

What is a resin 3D printer used for?

A resin 3D printer is used for a variety of applications that require high-detail, intricate, and precise three-dimensional objects. Some common uses of resin 3D printing include:

- Prototyping: Resin 3D printing is often used to create detailed prototypes of products before they go into full-scale production. The high level of detail and accuracy helps engineers and designers test and validate their designs before committing to expensive manufacturing processes.

- Jewelry: The fine details achievable with resin 3D printing make it a popular choice for creating intricate jewelry designs. Jewelers can produce complex and customized pieces with ease.

- Dental and Medical Models: Resin 3D printing is used in dentistry and medicine to create accurate models of teeth, bones, and other anatomical structures. These models aid in treatment planning, surgical preparation, and educational purposes.

- Miniatures and Figurines: Hobbyists and enthusiasts use resin 3D printers to produce highly detailed miniatures, figurines, and models for tabletop gaming, collectibles, and artistic displays.

- Art and Sculpture: Artists use resin 3D printing to bring their creative visions to life, producing intricate sculptures, intricate designs, and unique artworks that might be challenging to create using traditional methods.

- Consumer Goods: Resin 3D printing is employed in the production of small consumer goods, such as phone cases, custom buttons, and decorative items that require intricate details.

- Rapid Tooling: Resin 3D printing can be used to create molds, dies, and other tooling components for various manufacturing processes, providing a rapid and cost-effective way to produce these tools.

- Architectural Models: Architects and urban planners use resin 3D printers to create detailed scale models of buildings, landscapes, and urban environments to better visualize and communicate design concepts.

- Education and Research: Resin 3D printing is used in educational settings to teach students about 3D printing technology and its applications. Researchers also use these printers for producing prototypes and research models.

- Customized Products: The ability to create highly detailed and customizable objects makes resin 3D printing suitable for producing personalized items like custom-fit accessories, orthotics, and specialized components.

It’s important to note that while resin 3D printing offers numerous advantages in terms of detail and precision, it also has some limitations, such as limited build volume, the need for proper ventilation due to fume emissions, and the post-processing steps required to clean and cure the printed objects. The choice of printer, resin material, and design considerations all play a role in determining the suitability of resin 3D printing for a specific application.

Is resin 3D printing stronger than PLA?

Resin 3D printing and PLA (Polylactic Acid) filament-based 3D printing are two different technologies with their own strengths and weaknesses in terms of strength and durability.

In general, parts produced using resin 3D printing can have higher resolution and smoother surfaces compared to those printed with PLA, due to the nature of the printing process. However, when it comes to strength, there are several factors to consider:

- Mechanical Properties: Resin 3D printed parts can have different mechanical properties depending on the type of resin used. Some resins are specifically formulated to be strong and durable, making them suitable for functional parts. However, resin parts can be more brittle compared to PLA, and their strength might vary based on the resin’s formulation and curing process.

- PLA: PLA is a thermoplastic filament that is commonly used for FDM (Fused Deposition Modeling) 3D printing. PLA parts are generally less brittle than resin parts and can exhibit good layer adhesion, which contributes to their strength. PLA is suitable for a wide range of applications and can be relatively strong depending on the print settings and design.

- Layer Adhesion: PLA 3D printing often produces parts with good layer adhesion, which can contribute to the overall strength of the printed object. Resin 3D printing, on the other hand, doesn’t have visible layers like FDM printing, but the curing process can lead to less predictable layer-to-layer bonding.

- Orientation and Design: The orientation in which an object is printed can significantly affect its strength. Both resin and PLA parts can be stronger when printed with certain orientations that align with the expected mechanical loads. Additionally, design considerations such as wall thickness, infill, and geometry play a significant role in determining the strength of 3D printed parts.

- Post-Processing: Resin parts often require post-processing steps like curing under UV light and washing in isopropyl alcohol to achieve their final properties. These steps can affect the final strength and durability of the part.

In summary, whether resin 3D printing is stronger than PLA depends on various factors including the type of resin used, the specific application, print settings, and post-processing steps. PLA tends to have better layer adhesion and can be less brittle than some resin prints, but resin prints can achieve higher levels of detail and smoother surfaces. When selecting a 3D printing technology for a specific project, it’s important to consider both the desired properties of the final part and the limitations of the chosen printing method.

Is resin 3D printing good for beginners?

Resin 3D printing can be suitable for beginners, but there are certain factors to consider before diving into this technology:

Advantages for Beginners:

- High Detail and Quality: Resin 3D printing can produce highly detailed and high-quality prints with smooth surfaces. This can be visually impressive and satisfying for beginners.

- Minimal Warping and Adhesion Issues: Resin printing doesn’t suffer from the same warping and adhesion challenges that can affect filament-based (FDM) 3D printing. This can make the printing process more predictable.

- Less Complex Calibration: Resin printers often require less calibration and fine-tuning compared to some FDM printers, which can make them easier for beginners to set up and start printing.

Considerations for Beginners:

- Safety and Ventilation: Resin printing involves the use of UV light and the emission of potentially harmful fumes. Adequate ventilation and proper safety precautions are crucial.

- Post-Processing: Resin prints require post-processing steps like cleaning, curing, and potentially sanding or polishing. This can add complexity and time to the printing process.

- Cost: Both the upfront cost of a resin printer and the ongoing cost of resin materials can be higher compared to some entry-level FDM printers.

- Learning Curve: While the printing process itself might be simpler in some aspects, beginners still need to learn about resin types, print settings, and post-processing techniques.

- Size Limitations: Resin printers often have smaller build volumes compared to FDM printers. This can limit the size of objects you can create.

If you’re a beginner interested in resin 3D printing, here are some tips:

- Research: Take the time to research different resin printers, their features, and user reviews. Look for models that are known for being beginner-friendly.

- Safety: Prioritize safety by working in a well-ventilated area and using appropriate protective gear, such as gloves and safety glasses.

- Start Small: Begin with smaller and simpler prints to get familiar with the process and gain confidence.

- Follow Guidelines: Read and follow the manufacturer’s instructions for your printer and resin to ensure successful prints.

- Learn Post-Processing: Understand the post-processing steps required for resin prints, including cleaning, curing, and finishing.

- Seek Community Support: Online forums, communities, and tutorials can provide valuable insights and troubleshooting help.

In conclusion, while resin 3D printing has advantages for beginners in terms of print quality and calibration, it also comes with safety considerations, post-processing steps, and costs. If you’re willing to learn and follow safety guidelines, resin printing can be a rewarding choice for beginners looking to create high-detail, intricate objects.

Is it worth getting a resin 3D printer?

Deciding whether it’s worth getting a resin 3D printer depends on your specific needs, preferences, and intended use cases. Here are some factors to consider when making this decision:

Advantages of Resin 3D Printing:

- High Detail and Accuracy: Resin 3D printers are capable of producing extremely detailed and high-resolution objects. If you require intricate designs or small-scale models with fine details, resin printing might be a better choice.

- Smooth Surface Finish: Resin prints typically have smoother surface finishes compared to filament-based prints, which can be advantageous for certain applications like jewelry, figurines, and parts that require a polished appearance.

- Diverse Material Options: Resin printers offer a variety of specialized materials, including flexible, translucent, and engineering-grade resins, allowing you to choose materials tailored to specific project requirements.

- Complex Geometries: Resin printing can handle complex geometries, overhangs, and unsupported features better than some filament-based printers.

- Minimal Layer Lines: Resin prints don’t exhibit visible layer lines due to the nature of the curing process, making them more suitable for projects where aesthetics are crucial.

Considerations and Limitations:

- Cost: Resin 3D printers tend to be more expensive upfront than some filament-based printers. Additionally, the cost of resin materials can add up over time.

- Post-Processing: Resin prints require post-processing steps, such as cleaning, curing, and potentially sanding or polishing, which can be time-consuming and require additional equipment and materials.

- Ventilation and Safety: Resin 3D printing emits fumes during the printing and post-processing stages. Proper ventilation and safety precautions are important when working with resin printers.

- Build Volume: Resin printers often have smaller build volumes compared to filament-based printers. This could limit the size of objects you can create.

- Durability: Resin prints can be more brittle compared to certain filament-based prints, depending on the resin type and curing process.

Should You Get a Resin 3D Printer:

A resin 3D printer might be worth it if you prioritize high detail, intricate designs, and smooth surfaces in your projects. It’s a good fit for applications like jewelry making, dental models, miniatures, and artistic projects. However, if you primarily need functional prototypes, larger parts, or cost-efficient printing, a filament-based printer might be a better choice.

Before purchasing a resin 3D printer, carefully assess your budget, the specific types of projects you’ll undertake, your workspace’s ventilation setup, and your willingness to invest time in post-processing. Research the available models, read reviews, and consider seeking advice from experienced users to make an informed decision based on your unique needs and goals.

How much does a good resin 3D printer cost?

The cost of a good resin 3D printer can vary widely depending on the brand, features, build volume, and overall quality of the machine. As of my last knowledge update in September 2021, here’s a general price range you might expect for a good resin 3D printer:

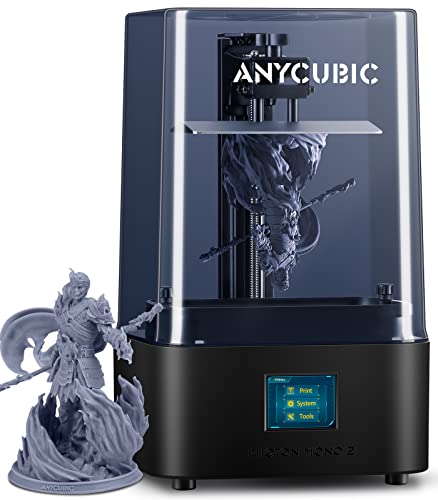

- Entry-Level Models: Entry-level resin 3D printers with smaller build volumes and basic features can start around $200 to $500. These models are suitable for hobbyists, beginners, and those looking to explore resin printing without a significant investment.

- Mid-Range Models: Resin printers with larger build volumes, better build quality, improved user interfaces, and more advanced features can fall in the range of $500 to $1500. These printers are suitable for those who want a balance between quality and affordability.

- Professional Models: Higher-end resin 3D printers with even larger build volumes, higher precision, industrial-grade components, and advanced features can range from $1500 to several thousand dollars. These models are often used by professionals in industries such as dentistry, jewelry making, and prototyping.

It’s important to note that the cost of the printer itself is just one aspect of the overall expense. You also need to consider the cost of resin materials, which can vary based on the type and brand. Additionally, factor in any potential costs for accessories (like curing stations, UV lights, and safety equipment) and ongoing maintenance.

Keep in mind that technology evolves quickly, and new models with different features and price points may have been introduced since my last update. Before making a purchase, thoroughly research the current market, read user reviews, and compare different models to find the best resin 3D printer that fits your budget and requirements.

Is 3D resin expensive?

The cost of 3D printing resin can vary depending on factors such as the brand, type of resin, color, and quantity purchased. Generally, resin materials for 3D printing are relatively more expensive than filament materials used in Fused Deposition Modeling (FDM) 3D printers.

As of my last knowledge update in September 2021, here’s an approximate range of resin costs:

- Standard Resins: Basic, standard resins can cost anywhere from $20 to $50 per liter or bottle. These resins are usually used for general-purpose printing and might not have specific enhanced properties.

- Specialized Resins: Resins designed for specific purposes, such as high temperature resistance, flexibility, or dental applications, tend to be more expensive. Their prices can range from $50 to $100 or more per liter or bottle.

- Premium and High-Performance Resins: Resins that offer exceptional properties, like extreme durability, high accuracy, or specialized characteristics, can be quite expensive. Prices for premium resins can exceed $100 per liter or bottle.

It’s important to consider the cost per part as well. Smaller and more intricate prints consume less resin, while larger prints or those with higher infill ratios will require more resin. Also, factor in the waste that occurs during support structures and failed prints, as these will add to the overall cost.

Additionally, the availability of resin types and their prices can change over time as technology advances and new formulations are introduced. It’s advisable to research and compare resin prices from various manufacturers and suppliers to find the best balance between cost and the properties you require for your specific projects.

Can you wear 3D printed resin?

Yes, you can wear 3D printed resin objects, but there are a few important considerations to keep in mind:

- Safety and Biocompatibility: Not all 3D printing resins are safe for direct skin contact or prolonged wear. Some resins may contain chemicals or additives that could cause skin irritation or allergic reactions. If you plan to wear a 3D printed resin object, make sure to choose a resin that is explicitly labeled as skin-safe or biocompatible by the manufacturer.

- Post-Processing: Proper post-processing is crucial when creating 3D printed objects that will be worn. After printing, resin objects need to be thoroughly cleaned and properly cured to ensure they are fully cured and safe for contact with skin. Incomplete curing could lead to residual chemicals that might be harmful.

- Design and Comfort: Consider the design and comfort of the 3D printed object. Objects that will be in direct contact with the skin, such as jewelry, should have smooth surfaces and no sharp edges that could cause discomfort or injury.

- Regulations and Certifications: Depending on your location and the intended use of the 3D printed object, there might be regulations or standards related to wearable items that you need to adhere to. For example, jewelry might need to meet certain quality and safety standards.

- Allergies: Some people may be sensitive or allergic to certain materials, including those used in 3D printing resins. If you or the person wearing the object has known allergies, it’s advisable to consult with a medical professional before using 3D printed items.

- Testing and Prototyping: Before creating a final wearable piece, it’s a good idea to create a prototype and test it for comfort, fit, and potential skin reactions. This can help you identify any issues before investing in the final piece.

In summary, you can wear 3D printed resin objects, but safety, material selection, proper post-processing, and comfort are all critical factors to consider. Always choose resins labeled as suitable for skin contact, follow proper post-processing steps, and consider any regulations or standards that might apply to wearable items.

Factors to consider when buying resin 3d printer

When buying a resin 3D printer, several important factors should be considered to ensure you choose a model that aligns with your needs and preferences. Here are some key factors to consider:

- Print Quality and Resolution: Look for a printer with high resolution capabilities for detailed and intricate prints. Check the layer height settings the printer offers and its track record in producing fine details.

- Build Volume: Consider the size of the objects you plan to print. Choose a printer with a build volume that accommodates your desired print sizes.

- Printing Speed: The speed of resin printing can vary between models. Faster printing can be desirable, but not at the expense of print quality.

- Type of Resin: Different printers are compatible with different types of resins. Make sure the printer you choose supports the type of resin you intend to use (e.g., standard, flexible, dental, engineering).

- Ease of Use and User Interface: A user-friendly interface can simplify the printing process, especially for beginners. Look for printers with intuitive software and user-friendly controls.

- Leveling and Calibration: Some resin printers require manual leveling and calibration. Consider whether you’re comfortable with these tasks or prefer a printer with automated leveling systems.

- Safety Features: Resin printing involves UV light and chemicals. Check if the printer has safety features like enclosed build chambers, UV-blocking covers, and safety interlocks.

- Ventilation: Proper ventilation is crucial to remove fumes emitted during printing. Ensure you have a well-ventilated workspace or consider additional ventilation solutions.

- Post-Processing Requirements: Resin prints require post-processing steps like cleaning, curing, and potentially sanding or polishing. Consider the post-processing equipment you’ll need.

- Software Compatibility: Check the compatibility of the printer’s software with your operating system and your preferred modeling software.

- Support and Community: Research the manufacturer’s reputation for customer support and the availability of user communities or forums for troubleshooting and advice.

- Reviews and Recommendations: Look for reviews from other users to gain insights into the printer’s performance, reliability, and user experience.

- Price and Budget: Set a budget for your printer and consider the additional costs of resin, post-processing equipment, and any accessories.

- Future Expansion: Consider whether the printer supports future upgrades or expansion options, such as dual-extrusion or different resin types.

- Brand Reputation: Established and reputable brands often offer more reliable products with better customer support.

- Warranty and Support: Check the warranty duration and coverage provided by the manufacturer. Understand the support options available in case you encounter issues.

- Availability of Spare Parts: Ensure that replacement parts and consumables are readily available for the printer.

- Industrial vs. Hobbyist: Determine whether you need an industrial-grade printer for professional use or a hobbyist-level printer for personal projects.

Remember that the best resin 3D printer for you will depend on your specific needs and preferences. It’s important to thoroughly research different models, read user reviews, and consider your own experience level before making a decision.

How long does resin 3d printer last?

The lifespan of a resin 3D printer depends on a number of factors, including the quality of the printer, the frequency of use, and the maintenance procedures followed. However, in general, a resin 3D printer can last for several years with proper care.

Here are some things you can do to extend the lifespan of your resin 3D printer:

- Store the printer in a cool, dry place.

- Clean the printer regularly, following the manufacturer’s instructions.

- Replace the FEP film and LCD screen as needed.

Use high-quality resin. - Avoid overexposure to UV light.

With proper care, your resin 3D printer can last for many years and provide you with years of enjoyment.

Here are some additional details about the factors that can affect the lifespan of a resin 3D printer:

- Quality of the printer: A higher-quality printer will typically last longer than a lower-quality printer. This is because higher-quality printers are made with more durable materials and components.

- Frequency of use: A printer that is used frequently will wear out more quickly than a printer that is used less often. This is because the printer’s components will be subjected to more wear and tear.

- Maintenance procedures: Following the manufacturer’s recommended maintenance procedures will help to extend the lifespan of your printer. This includes cleaning the printer regularly, replacing worn components, and using high-quality resin.

Are resin 3D prints fragile?

Resin 3D prints can be relatively more fragile compared to some other types of 3D prints, such as those made from tougher filaments like ABS or nylon in filament-based 3D printing. However, the degree of fragility can vary depending on several factors:

- Resin Type: Different types of resins have varying levels of strength and durability. Some resins are formulated to be more rigid and sturdy, while others might be more flexible or brittle.

- Print Settings: Adjusting the print settings, such as layer height and exposure times, can influence the final strength of resin prints. Prints with finer layer heights and optimal exposure settings can result in stronger parts.

- Geometry: The design and geometry of the object being printed can impact its strength. Designs with thin walls, unsupported overhangs, or delicate features might be more prone to breaking.

- Post-Processing: Proper post-processing is essential for achieving the desired strength in resin prints. Curing the printed object properly under UV light and post-curing if required can enhance its mechanical properties.

- Orientation: The orientation in which an object is printed can affect its overall strength. Printing in a way that aligns with the expected mechanical loads can result in a stronger part.

- Resin Properties: Some resins are formulated with specific mechanical properties in mind, such as impact resistance or flexibility. Choosing the right resin for your intended application can help achieve the desired level of strength.

It’s important to note that while resin prints might be relatively more fragile compared to certain other materials, they can still be suitable for a wide range of applications. For example, resin prints are often used for producing intricate jewelry, dental models, miniatures, and prototypes. If you need parts with higher impact resistance or durability, you might need to explore tougher resin formulations or other 3D printing materials.

Ultimately, the strength of a resin 3D print depends on the resin type, print settings, design considerations, and post-processing steps. Careful selection of these factors can help you create resin prints that meet your specific strength requirements.

Should you buy resin 3d printer?

In conclusion, resin 3D printing offers a range of advantages and considerations that should be carefully weighed when considering whether it’s the right choice for your needs. Resin 3D printers excel in producing high-detail, intricate objects with smooth surfaces, making them popular for applications like jewelry making, figurines, dental models, and more.

Before purchasing a resin 3D printer, thoroughly research the available models, read user reviews, and consider your intended use cases. It’s crucial to have a clear understanding of safety procedures, post-processing requirements, and potential costs associated with resin printing. If the benefits align with your needs and you’re willing to invest time and effort into learning the technology, a resin 3D printer could be a powerful tool for creating detailed, high-quality objects.

You May Also Like These Deals!

What is Toybox 3d printer used for?

The Toybox 3D Printer is a revolutionary device that empowers...

Read MoreBest All In One Wireless Printer Black Friday Deals

With so many great all-in-one wireless printers on the market,...

Read MoreBest Portable Photo Printer Black Friday Deals

There is nothing quite like having a photo to keep...

Read MoreProducts recommended in the post contain affiliate links. We may receive a commission when you buy something through our posts.

Why Trust Us

You will find what you are looking for at Black Friday Weeks. From classic to luxury brands, you'll find both. We will help you to select appliances that fit your needs, budget and lifestyle. Whether you want to stop by to learn more — or plan to make a major purchase — we’ll treat you like family and assist you every step of the way. Shop with us today to receive friendly and experienced help along the way.